Helicopter: Rapid Aerodynamics

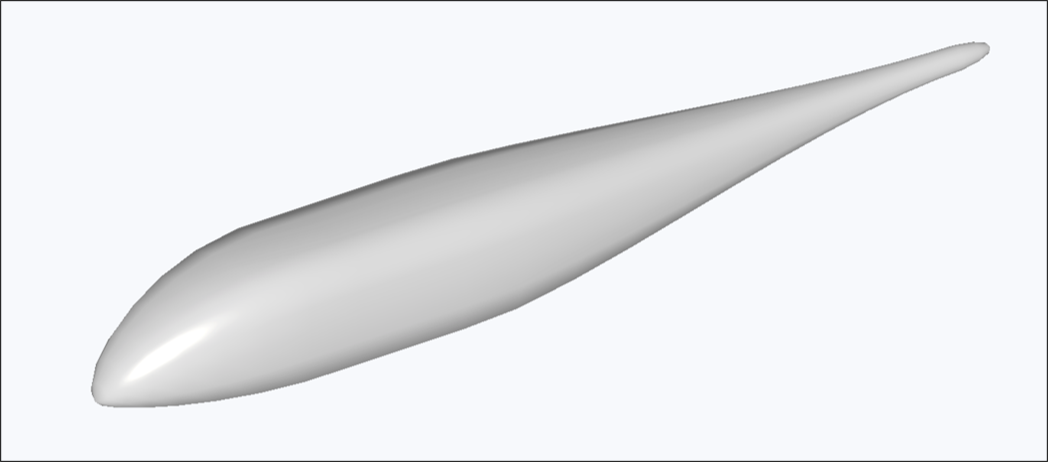

Target Aircraft Information

- Fuselage length: 0.4 m

- Fuselage width: 0.05 m

- 1 main rotor

- Diameter: 0.32 m

- Airfoil: NACA-0012

- RPM: 3000

- 1 tail rotor

- Diameter: 0.12 m

- Airfoil: NACA-0012

- RPM: 4000

Download Sample STL File

Download the sample STL file to follow along with this tutorial:

Step 1: Import CAD Geometry

- Navigate to the Rapid Aerodynamics module

- Click the Import CAD button

- Select the

robin_fuselage_ASC2_scale.stlfile - Verify that the import completed successfully

Important Notes:

- STL files must contain less than 2000 surface elements

- Geometry is directly reflected in the analysis without modification

- Ensure proper scale and units before importing

Step 2: Configure Propellers

When creating multiple identical propellers, you can define the blade geometry first and then copy the propeller. This allows the blade geometry information to be copied for faster workflow.

2.1. Blade Configuration

- Select Airfoil: NACA-0012

- Number of Blades: 2

- Blade Section Data: Configure as follows

- Radial Position: Distance from propeller center [m]

- Chord Length: Blade width (chord line length) at this section [m]

- Twist Angle: Pitch angle of the blade section [°]

- Twist Position: Chord-wise position of twist axis (0 ~ 100)

Main rotor

[radius, chord, twist, twist axis]

0.02, 0.01, 10, 25

0.04, 0.015, 15, 25

0.06, 0.02, 20, 25

0.08, 0.02, 20, 25

0.14, 0.015, 15, 25

0.16, 0.01, 10, 25

Tail rotor

[radius, chord, twist, twist axis]

0.01, 0.005, 10, 25

0.02, 0.008, 15, 25

0.03, 0.01, 20, 25

0.05, 0.008, 15, 25

0.06, 0.005, 10, 25

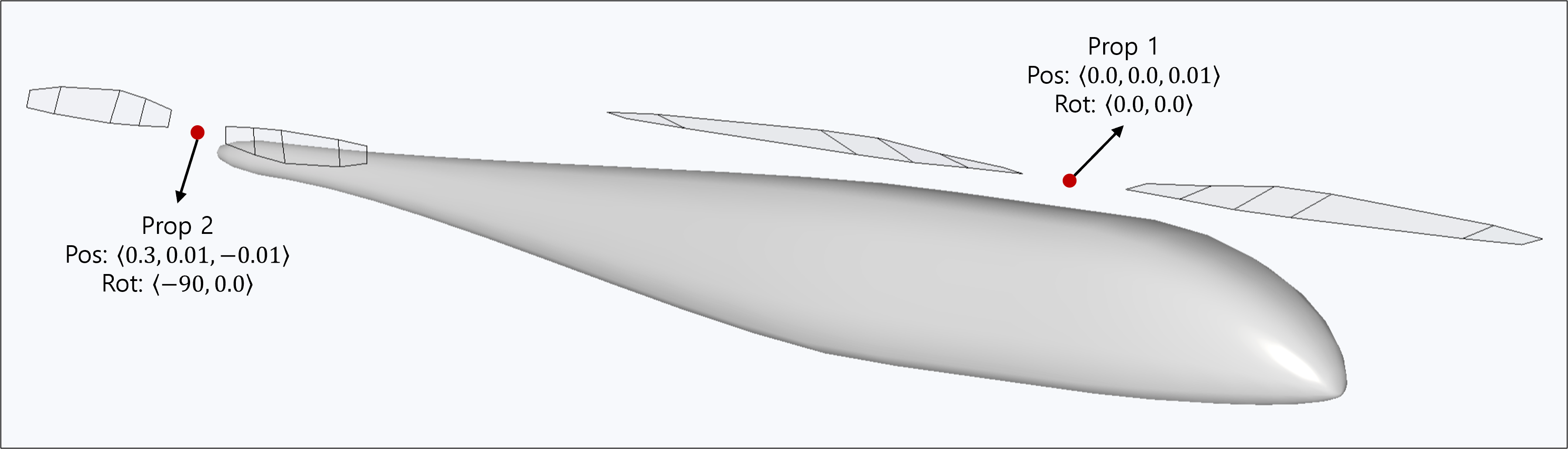

2.2. Propeller Placement

Refer to the figure above to set the propeller placement positions:

prop 1: Position <0.0, 0.0, 0.01>, Rotation <0.0, 0.0>

prop 2: Position <0.3, 0.01, -0.01>, Rotation <-90, 0.0>

Step 3: Configure Simulation Settings and Run

3.1. Simulation Settings

- Simulation Style, Enable VPM: User's choice

- Flow Velocity: 10 m/s

- Number of Cores: 8 or more recommended

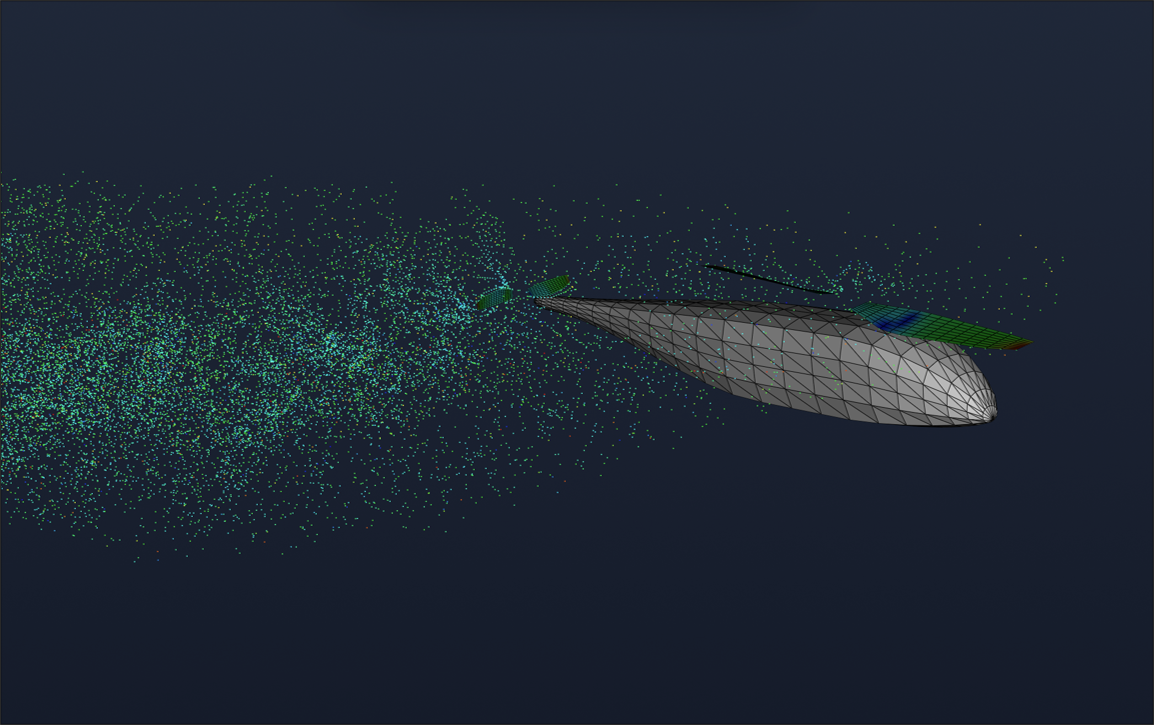

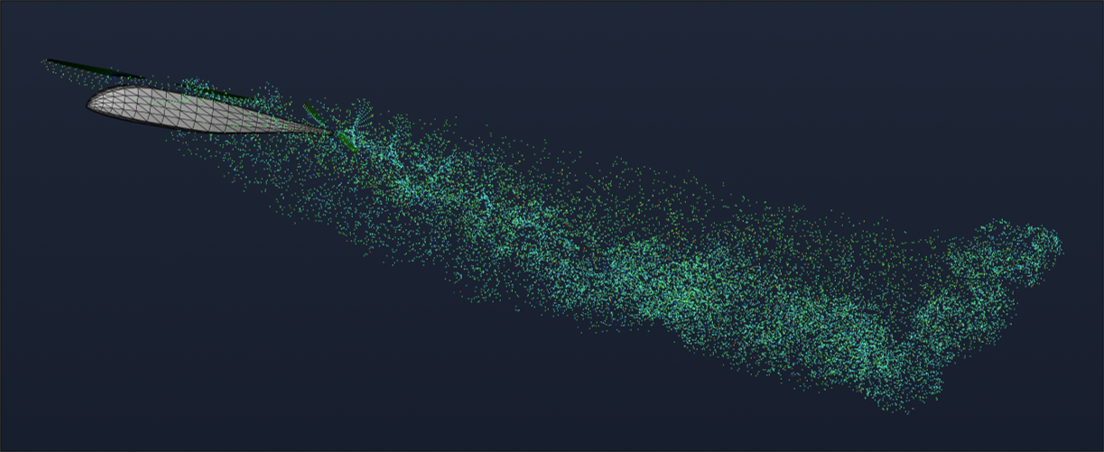

Step 4: Visualize Results

Visualization is primarily used to review whether the flow analysis results are physically reasonable. In this analysis, we mainly examine the following phenomena:

- Strong circulation at blade tips

- Circulation generated by main rotor and tail rotor

- Movement of circulation due to forward flight

Step 5: Review Reports

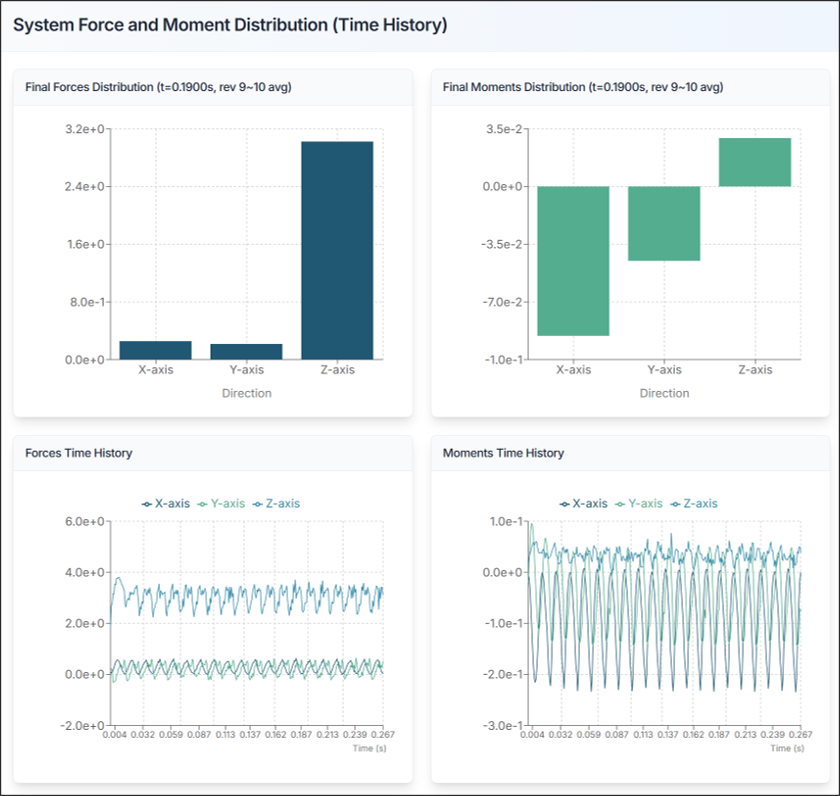

5.1. System Forces and Moments

Review the forces acting on the entire aircraft:

- Fx, Fy, Fz: Forces in x, y, z directions [N]

- Mx, My, Mz: Moments about x, y, z axes [N·m]

Analysis Tips:

- Total Thrust (Fz): Should match expected lift requirements

- Moments: Should be balanced for stable flight

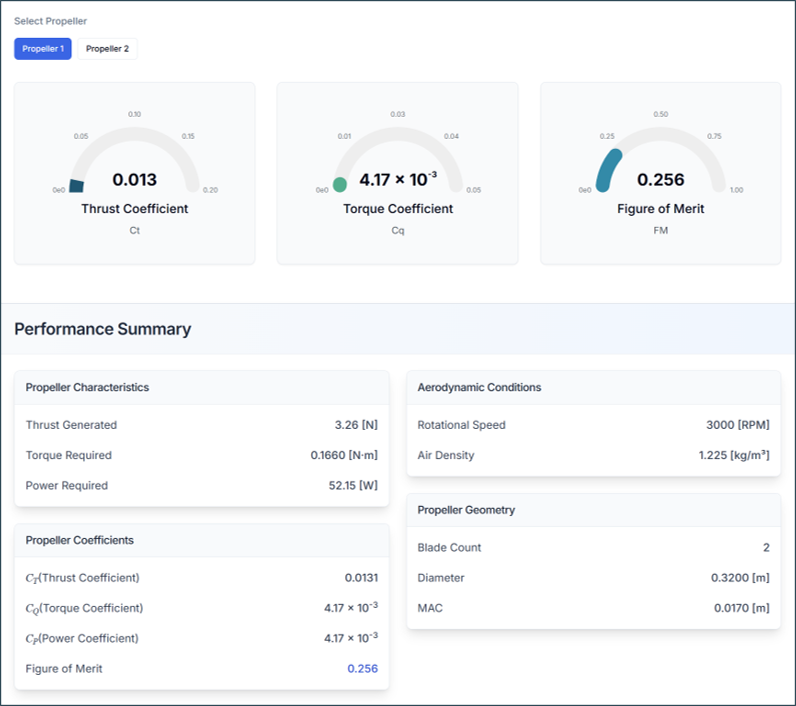

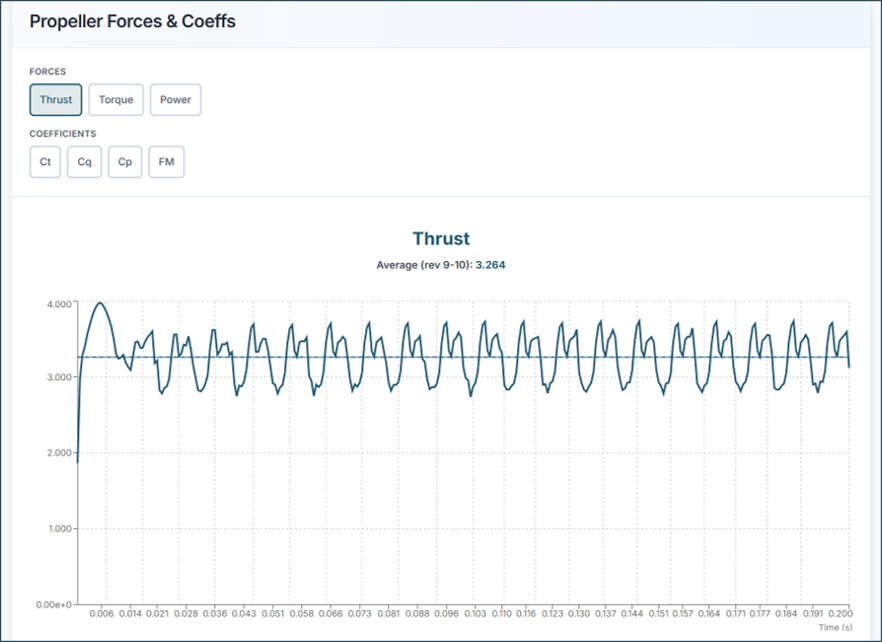

5.2. Propeller Performance

Thrust Coefficient (Ct)

- Higher Ct = more thrust per revolution

- Typical range: 0.08 - 0.15

Torque Coefficient (Cq)

- Represents power requirement

- Lower Cq = more efficient

Power Coefficient (Cp)

- Indicates power consumption

- Related to motor requirements

Figure of Merit (FM)

- FM must be < 1.0

- Typical range: 0.6 - 0.85

- Higher FM = more efficient propeller

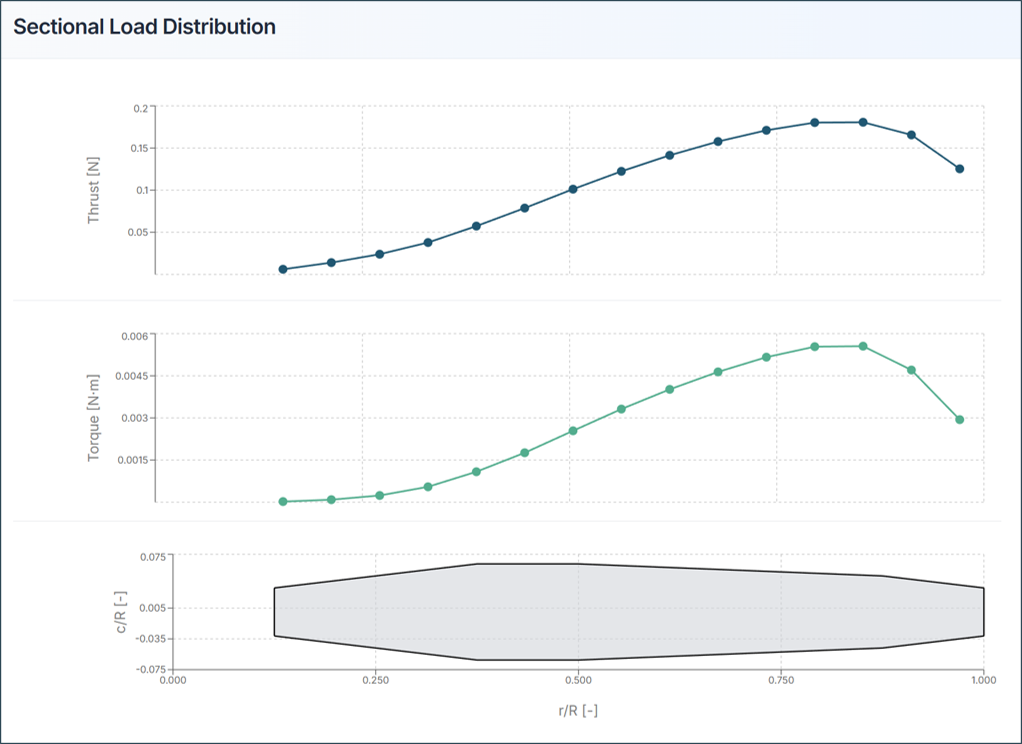

5.3. Sectional Load Distribution

Thrust Distribution Graph:

- X-axis: Radial position (0 = hub, 1 = tip)

- Y-axis: Local thrust

- Ideal: Smooth curve with peak near blade mid-span

Torque Distribution Graph:

- Shows power requirement along blade

- Helps identify high-load regions

- Useful for structural design

Design Insights:

- Peak loads at 70-80% radius: Good design

- High tip loads: Risk of tip stall

- Uneven distribution: Consider blade redesign

Aircraft Design Tips and Troubleshooting

1) If Thrust is Insufficient

- Increase RPM

- Add more blades

- Increase blade chord length

- Increase twist angle

2) If Propeller Efficiency is Low

- Optimize blade twist distribution

- Reduce tip losses with winglets

- Improve airfoil selection

- Reduce blade interference

3) If Aircraft Moments or Forces Show Stability Issues

- Balance propeller forces

- Adjust propeller positions

- Verify moment distribution

- Check symmetric configuration

4) STL Import Failure

- Solution: Verify STL has < 2000 elements and proper format

5) Analysis Takes Too Long

- Solution: Use "Fast" mode, reduce blade sections, disable VPM

6) Results Appear Unrealistic

- Solution: Verify flow velocity + tip speed < Mach 0.7, check propeller configuration

7) Figure of Merit > 1.0

- Solution: Re-check input parameters, flow conditions, or RPM settings

Need Assistance or Have Questions?

Frequently Asked Questions: FAQ Link

Support Inquiries: support@everysim.io